Introduction

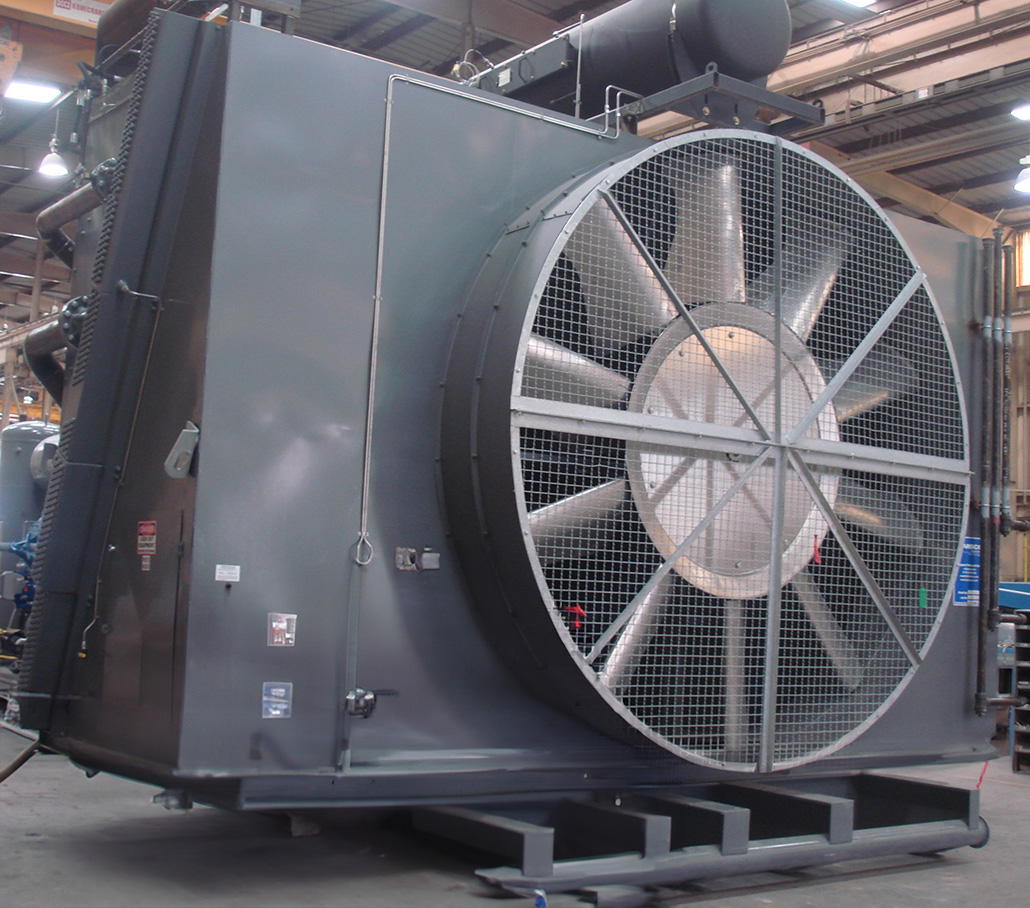

In the dynamic landscape of industrial machinery monitoring, VibScope emerges as a game-changing solution, offering unparalleled insights into machine behavior. Its sophisticated functionality, rooted in advanced statistical modeling, revolutionizes the way equipment health is perceived and managed. Let’s delve deeper into how VibScope’s cutting-edge capabilities redefine the landscape of machinery monitoring.

Key Points:

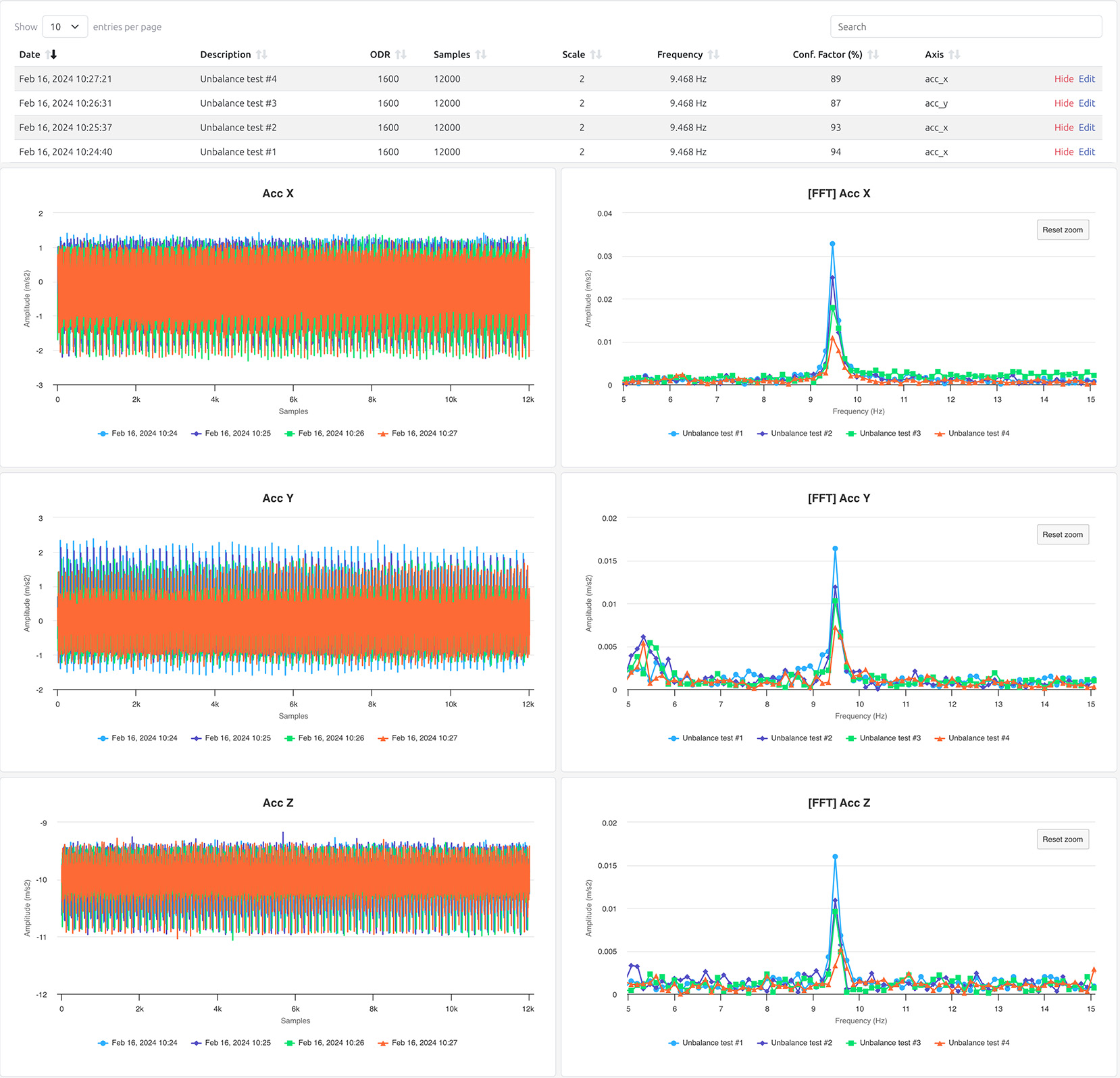

Acquiring Comprehensive Vibration Waveforms:

At the heart of VibScope’s functionality lies its ability to capture full vibration waveforms across multiple machine cycles. This comprehensive data acquisition process provides a holistic view of machine dynamics, offering invaluable insights into performance and operational integrity.

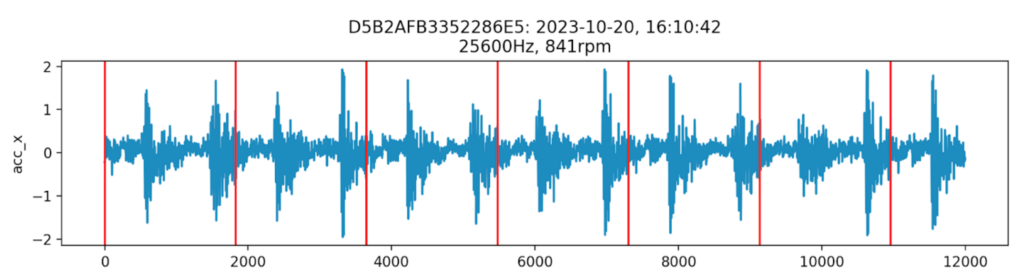

Generating Statistical Models:

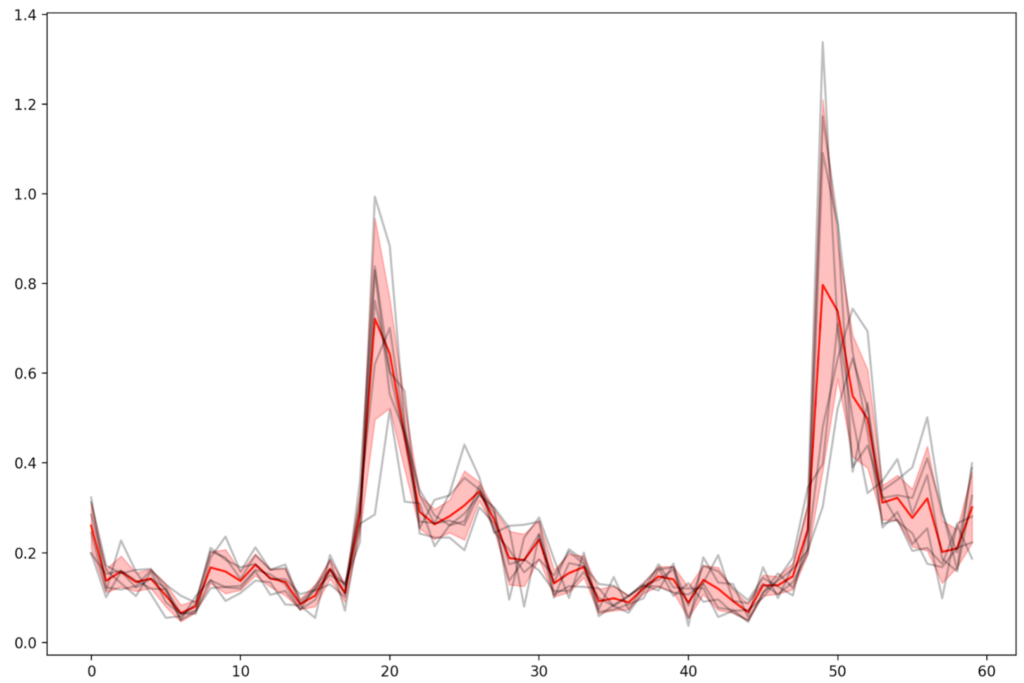

VibScope takes the acquired vibration waveforms and dissects them into small, identical segments. These segments serve as building blocks for generating robust statistical models that encapsulate the nominal behavior of the machine. By analyzing patterns and trends within the data, VibScope creates models that accurately depict the expected operational parameters.

Describing Machine Nominal Behavior:

The statistical models generated by VibScope serve as a benchmark for understanding the nominal behavior of the machine. These models encapsulate the typical vibration patterns exhibited during standard operation, providing a reference point for comparison and analysis.

Comparative Analysis:

With each new waveform acquisition, VibScope conducts a comparative analysis against the available statistical models. By evaluating the correlation between the acquired waveform and the nominal or fault models, VibScope identifies deviations from expected behavior. This real-time analysis enables proactive identification of potential issues and facilitates timely interventions.

Empowering Decision-Making:

The insights gleaned from VibScope’s statistical modeling capabilities empower maintenance teams to make informed decisions regarding equipment health and performance. By leveraging the data-driven assessments provided by VibScope, organizations can optimize maintenance schedules, minimize downtime, and enhance overall operational efficiency.

Conclusion:

VibScope’s advanced statistical modeling functionality represents a significant leap forward in machinery monitoring and maintenance. Its ability to capture comprehensive vibration waveforms, generate robust statistical models, and conduct comparative analysis revolutionizes the approach to equipment health management. As industries strive for greater efficiency and reliability, VibScope emerges as a indispensable tool in the pursuit of optimal performance and operational excellence.

CONTACT IMBU!

Ready to harness the power of VibScope for advanced machinery monitoring and maintenance? Contact us today to learn more about how VibScope can revolutionize your operations and propel your organization towards greater efficiency and reliability. Experience the future of equipment health management with VibScope.